Development of diaper core structure

Diapers on the market a wide range of products, they are mainly by the skin layer, diversion layer, absorption core, the back layer of these four parts.

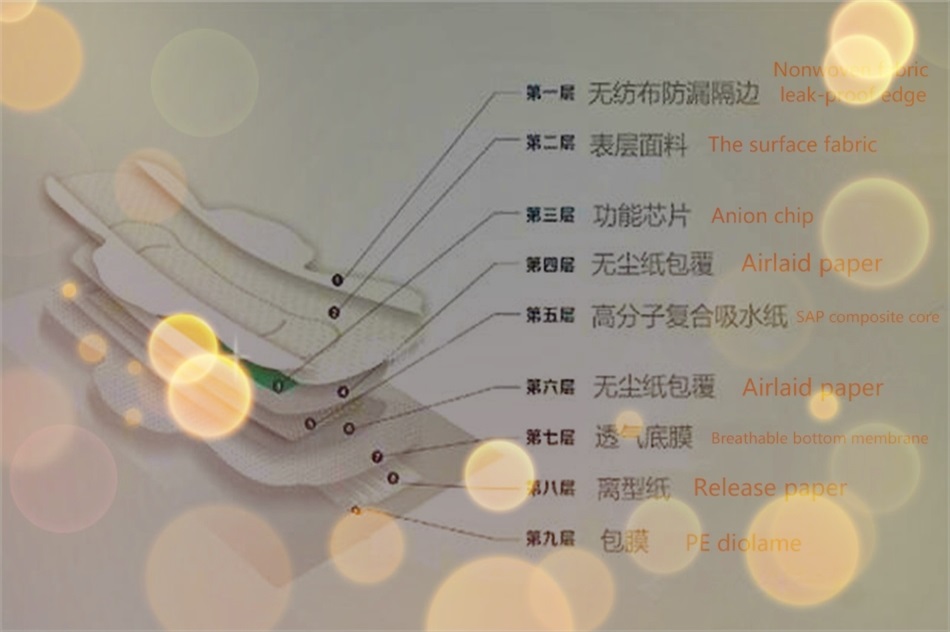

Sanitary napkin material

Do a sanitary napkin, not only to look practical, its multi-layer structure contains a variety of exquisite technology, a lot of important materials are playing a different role.We generally spread sanitary napkin structure has what important materials.

MEIDEN R & D Center

The company has established MEIDEN R&D Center and Huaheng R&D Center together with the top team in the domestic industry

MEIDEN has large production and wide sales

MEIDEN has large output and wide sales volume, and has cooperated with thousands of enterprises, with customers all over the world!

Development of diaper core structure

At present, the change of world population structure has brought about great development potential for the global diaper market. The implementation of baby policies and the change of parenting concepts in various countries have greatly stimulated the development of the diaper market for infants.At the same time, the aging of the population increasingly serious, adult diapers market curtain has been opened, and into the rapid growth period.

The diapers on the market are full of beautiful things in eyes, but they are mainly composed of skin-friendly surface layer, diversion layer, absorption core body, and dorsal layer.Among them, the absorption core is the most important structural component in diapers. As the main absorption layer, it is required to absorb urine quickly and spread urine to the whole absorption core by the use of diversion and core absorption. Then, the absorbent resin (SAP) can quickly absorb and lock urine, and make it non-reverse osmosis.

Absorption core development process

In 1960, Procter & Gamble incorporated nonwoven materials and fluff pulp into diapers as absorbent core, which made diapers have certain applications.

In 1980, Unica added SAP on the basis of the original absorbent core, which made the diapers have certain liquid absorption and retention properties. It was called the first generation absorbent core.However, there is neither stratification nor partition inside the absorption core, and the problem of lumps will appear after the absorption, which will lead to the obstruction of urine transverse diffusion, and the excessive amount of liquid absorption in a certain area will affect the r everse osmosis performance of diapers.The absorption core of the second generation is divided on the basis of the first generation, which can fix the villus pulp and SAP to a certain extent, and reduce the problem of clumping after the diaper suction.

With the development of dry papermaking technology, namely dust-free paper technology, the third generation of absorbent core, namely composite absorbent core, was born by combining dust-free paper with porous fluffy nonwovens and SAP.The absorbent core is bonded between each layer of material by hot-melt adhesive, and the diaper becomes thinner.The absorbent core contains a large amount of SAP, and the absorbent volume of the diaper becomes larger.In addition, the mesh structure of porous fluffy nonwovens can fix SAP well, absorb fluid evenly from the core body, and expand vertically and horizontally into the whole body after absorbing fluid, making the surface of diapers smoother.

At present, most of the diapers made in China use the third-generation absorbent core.

The fourth-generation absorption core is further divided in the interior of the third-generation absorption core, and each layer is better fixed. The absorption core becomes thinner and lighter, but the technology is still being improved.

Analysis of absorption core structure

The absorption core can be divided into traditional absorption core and new composite absorption core according to the different compounding mode of villous pulp.

Traditional villi core structure

After urine is absorbed by diapers containing traditional villous pulp absorbing core body, villous pulp diffuses and conducts urine by virtue of its natural fiber advantages. Meanwhile, SAP can quickly absorb, expand and lock urine.SAP and villous pulp are loosely mixed in the absorbing core, and there is enough space inside the absorbing core for air permeability. Therefore, although the diaper is relatively thick, it has good air permeability after absorbing liquid.In addition, villus pulp can fix SAP to a certain extent, prevent SAP from moving and piling up, and keep the surface of diapers smooth and soft.In addition, the core-suction effect of fluff pulp can solve the problem of gel blockage after SAP suction, weaken the phenomenon that diapers are prone to glop after SAP suction, and improve the feeling of wearing comfort.But, in this kind of diapers, the wearer should avoid large mobile slip or flip in SAP, and caused the uneven distribution, SAP distribution areas more quickly and expansion and hinder the spread of urine, eventually lead to faults, tuo, influence of diapers fluid absorption for many times, more severe cases can cause surface film tear, urine leakage, stimulate the wearer of the skin.

A new type of composite absorption core

As diaper products become thinner and thinner, and people have higher and higher requirements on absorbent performance, new composite absorbent cores are emerging.It is usually coated with dust-free paper and porous fluffy nonwovens, then spread SAP between porous fluffy nonwovens, and then use hot melt glue to bond each layer.

The absorption core can be divided into traditional absorption core and new composite absorption core according to the different compounding mode of villous pulp.

The traditional villous pulp absorbing core is mainly composed of coating layer, SAP and villous pulp.SAP and villous pulp are mixed in a certain proportion to form SAP/villous pulp absorbent;The cladding layer is made of toilet paper or non-woven materials or multi-layer composite materials. The upper cladding layer usually has the functions of diversion and ventilation, while the lower cladding layer usually has the functions of anti-seepage and barrier.

In new type of composite absorbing core body, porous fluffy nonwoven material is one kind of hydrophilic materials, the grid structure can be stored and fixed a lot of SAP and the SAP distributed evenly, so the new type of composite absorbing core body after absorb the urine in the overall expansion, to avoid the fault appears after the absorption liquid and absorption core bodies tuo, diapers smoothness on the whole.At the same time, because there is no villous pulp added, the diapers containing the new composite absorption core body become very thin and light, the wearers feel less weight bearing, and the amount of SAP added will increase accordingly, and the amount of fluid absorbed by the diapers will increase.

However, this kind of absorption core also has some disadvantages. For example, without the support of villous pulp, SAP will form a gel shape after absorbing urine, and the feel of diapers will become harder and the permeability will become poor.Hot melt adhesive is used between each layer of materials to fix SAP, and more SAP requires more hot melt adhesive, which will lead to harder feel and worse air permeability of diapers, affected fluid absorption speed, and worse odor after fluid absorption;Ultra-thin composite absorbent cores generally have the defect that the absorbent speed is faster at the first time and then decreases seriously, while the traditional villous slurry absorbent core has a more balanced absorbent speed.With complex structure and many layers, it has lower production speed and higher production cost compared with the traditional villous pulp absorption core.

With the continuous improvement of people's requirements for lightweight, breathable, liquid absorbent, hygienic and non-stimulating diaper products, the diaper absorption core body will develop towards the direction of diversified and comprehensive functions, and the structure of the absorption core body will be continuously improved.Among them, the structural study of MEIDEN composite absorption core will bring new breakthroughs to the field of health products, which is conducive to grasping the needs of consumers, developing better new products, giving play to the potential of the global diaper market, increasing market penetration and expanding market share.

Sanitary napkin material

Sanitary napkin material

MEIDEN has large production and wide sales

MEIDEN has large production and wide sales

MEIDEN R & D Center

MEIDEN R & D Center